Summary:Precision Casting is a manufacturing technique that manufactures parts with complicated geometries a...

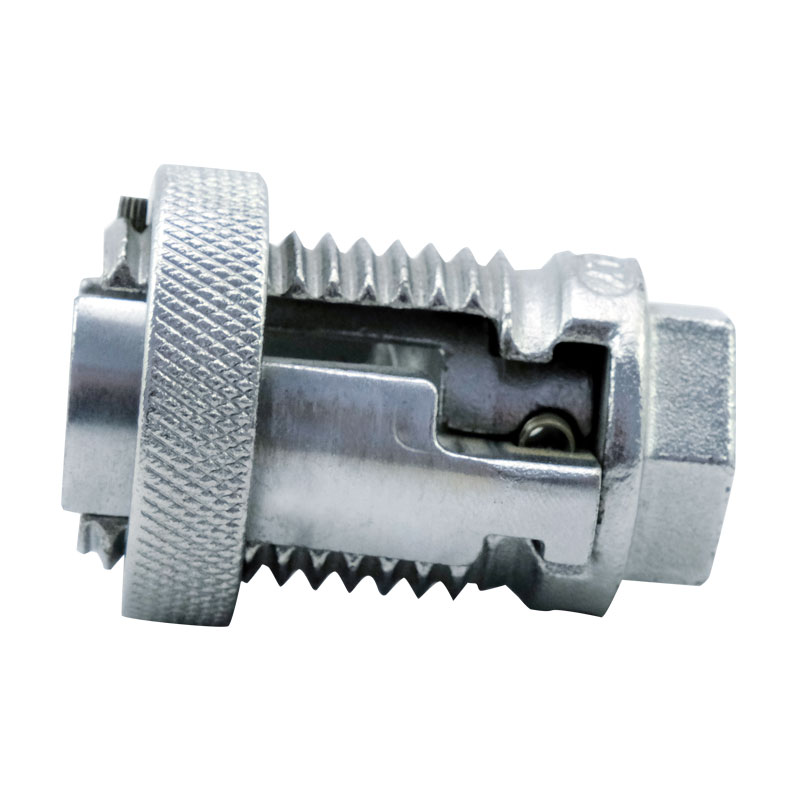

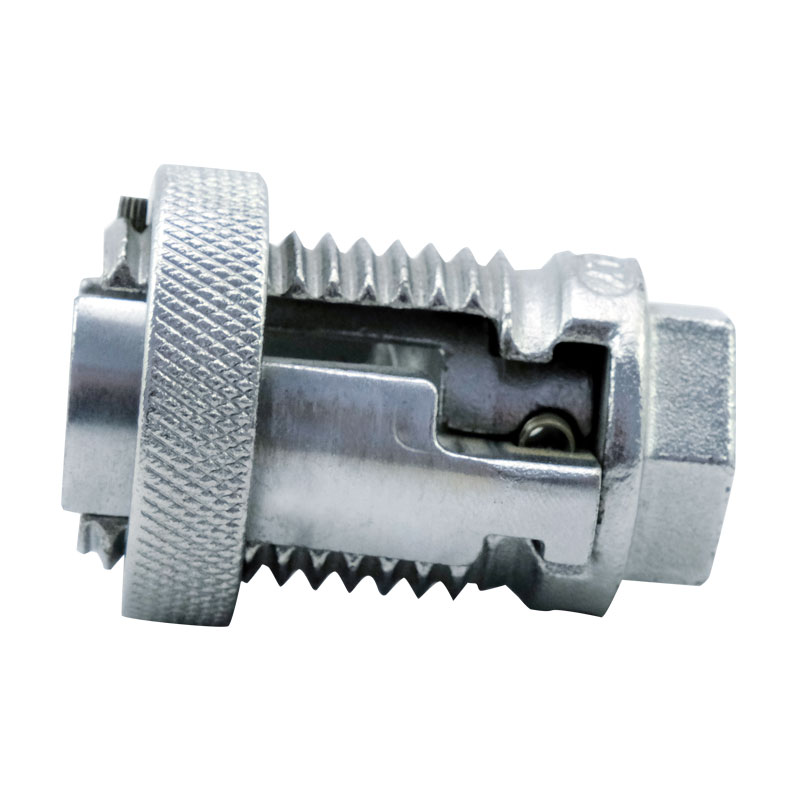

Precision Casting is a manufacturing technique that manufactures parts with complicated geometries and detailed designs. It is also called lost wax casting or investment casting.

Unlike other processes, precision casting allows for complex shapes that would otherwise be impossible to machine or forge. This means that it can be used to make turbine rotors, gears, and other products requiring highly intricate features.

Process Description:

The casting process involves the injection of molten metal into a mold cavity that is designed to mimic the final product's geometric shape. The molten metal is then allowed to cool and solidify.

This process is often used for prototype development and short-run production as the tooling costs are typically very low and the dimensional accuracy is excellent. This process also enables the forming of thin sections and recessed areas, which can be difficult to produce by other methods.

A ceramic shell is built around each pattern to create a strong and rigid casting structure. The molds are dipped in a ceramic slurry several times until the outer layer of the shell is thick enough to provide adequate strength for the molds.

After the waxes are removed from the molds (lost-waxing), the molds are fired to strengthen them, burn residual wastes, sinter the shells, and pre-heat the molds for the subsequent metal casting process.

Once the runner system and central gating system are in place, molten metal is poured into the mold. The runner system channels the metal into each cavity, while the central gating system provides a channel for molten metal to pass through as it fills the mold cavities.

Main:+86 574 87907106

Main:+86 574 87907106![]() Main:+86 574 87907106

Main:+86 574 87907106